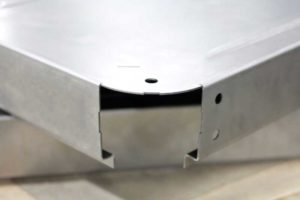

Automated and Versatile Press Brakes Providing Consistent Quality & Quick Turnaround for a Variety of Product Geometries at Competitive Prices

Micro Metals is an excellent choice when searching for a reliable metal forming partner with a long history of competitive costs and quality services. Centrally located in Colorado Springs, Micro Metals supplies local, national, and international partners.

With an assortment of 11 manual and 2 robotic press brake machines, Micro Metals has the flexibility and expertise to manufacture high-quality products from the small & straightforward to the large & complex, all across a large cross-section of materials and thicknesses.

Why Micro Metals?

For 5 decades, Micro Metals has invested in the latest technology, including CNC and robotic brake presses to ensure quality, consistency, and responsiveness.

- 50 years as a trusted single-source, full-service manufacturer

- A long-standing culture of teamwork, loyalty, and continuous improvement

Quality / Flexibility / Speed

The team at Micro Metals has had a top-down commitment to

quality, maintenance, production, design, and customer service

for over five decades. This culture drives defect-free affordable

services with minimal waste.

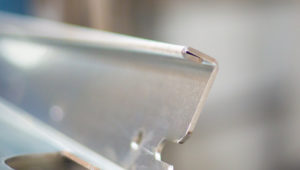

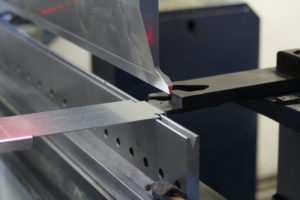

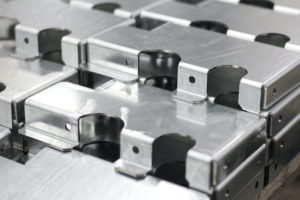

The variety of precision Press Brake Machines is just one of the turn-key capabilities that makes Micro Metals a one-stop shop for metal fabrication. Precision and speed are attained with CNC programmed manual presses and fully automated bending cells utilize robotics to transfer from flat sheets to completely formed and palletized parts.

State of the Art Equipment

Micro Metals offers the latest technology and capabilities with high-capacity robotic press brakes that deliver cost-effective consistency.

- 11 manual press brakes

- Force range up to 350 tons

- Tool lengths up to 16 ft.

- CNC 6-axis programmable process sequences for productivity and repeatability

- 2 Trumpf robotic press brake

- 253 tons force

- 167” bending length

- 220 lbs. max blank weight

Our Trusted Certifications & More

The Right Partner For Your Ongoing Needs

An Ongoing Commitment to Excellence

Micro Metals has a longstanding history of consistently providing products and services that meet and exceed customer requirements. Their commitment to quality, continuous improvement, and customer satisfaction is industry renowned. ISO-9001 accreditation* allowed the company to validate a quality management system that complies with internationally recognized statutory and regulatory recommendations.

*The International Organization for Standardization (ISO) is a worldwide federation of national standards bodies from more than 160 countries and the internationally recognized standard for excellence in all business areas

Team Commitment to Quality

The top-down commitment to quality has been integrated into all facets of the business. With an IATCA/IRCA Lead Auditor and eight trained Internal Auditors, ongoing continuous improvement is essential for customer satisfaction at Micro Metals.

- A family culture of highly skilled, genuinely caring people delivering quality products to the customer

- The “Go To” full-service manufacturer of high-quality, cost-effective, and affordable products.

Full-service customer support is the focus of the Micro Metals Engineering department. They are accomplished in the latest software, with expertise in various design and simulation programs.

From design from prototype to production, our team delivers affordable, accurate quotations and high-quality products. Engineering and manufacturing processes are constantly re-evaluated to ensure optimal production.

Value-Added/Value-Engineering (VA/VE) and Design for Manufacturing (DFM) support is also offered to our potential customers.

Contact us to see why customer service, reducing waste, and continuous improvement are the core values of our Engineering team.